Tropical Timber

DIN EN 13556: SMAM)

Botanical name: Simarouba amara, family Simaroubaceae

Distribution: Caribbean, Central America, northern South America

Trade and local names: caixeta, paraeúba, pitomba, tamanqueira (BR); simaruba (CO); capulli, cuña, guitarro (EC); amargo, chiriguamo (BO); aceituno (GT); olivo (CR); acajou blanc (GF); simarupa (GY); soemaroeba (SR); cedro blanco, chiriuana (VE); bitterwood, raintree (US)

Target title: Marupá - definition and characteristics

Short description: Simarouba amara is the only one of the five species of the genus Simarouba whose timber is traded regionally and on the international market, mainly under the standard Brazilian name Marupá. The most important exporting countries are Brazil and Peru, which supply sawnwood and plywood, but also various finished products to Mexico and the USA, and more recently also to Europe.

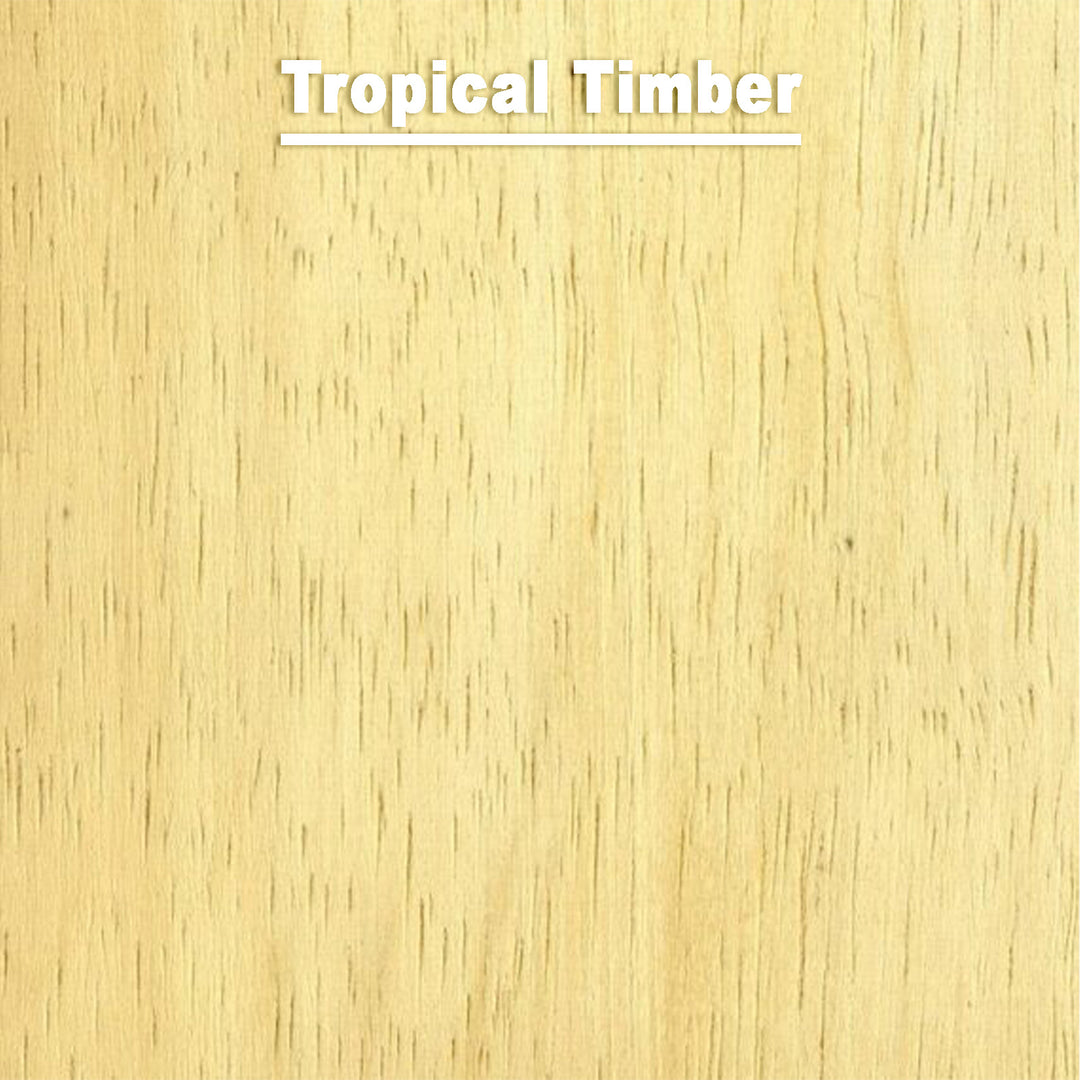

Color and structure: Heartwood and sapwood uniformly yellowish white or straw. Growth zone boundaries are not clearly marked. Wood with scattered pores, storage cells in cross section as light-colored, narrow, wavy bands. Grain mostly straight, sometimes also slightly alternate.

General character: Light-colored, matt-glossy wood, homogeneous structure, low to medium density, uniformly light color and generally coarse texture.

Machinability: The light wood and homogeneous structure allows clean machining with hand and machine tools. Marupá can be easily sawn, planed, milled, turned, drilled and transformed into peeled and cut veneers. Screws and nails are satisfactorily fastened. The homogeneous structure of the machined surfaces in combination with the uniformly light color allows a wide range of coloring by dyeing. Adhesion and surface treatment with commercially available preparations are no problem.

Drying: Marupá dries easily and quickly in the open air with a low risk of warping and cracking. The same applies to technical drying. It is especially important that as little time as possible elapses between cutting and drying to avoid quality losses due to fungal attack (blue stain).

nat. Durability: The wood is not durable and is very quickly attacked by fungi and insects that discolor and destroy the wood when fresh.

Areas of use: The low natural durability of wood limits its use to interior areas. Preferred applications are interior structural construction under low mechanical stress, furniture, profiled panels and boards, interior doors, plywood top and middle layers, musical instruments, picture frames, broomsticks, less frequently also for packaging, toys and matches.

Substitute woods: For similar light colored woods such as Ako (M-67), Lime (M-140), Primavera (M-122) as well as lighter grades of Birch (M-93), Ramin (M-27) and similar.

Notes: Occasionally traumatic resin channels occur in tangential bands. The resin does not crystallize and may flow and form stains when the surface is heated.

Bibliography: CIRAD-FORÊT: Tropix 7: Fiches techniques Version 7.5.1. Simarouba amara: tropix.cirad.fr/en Comvalius, L.B. 2001. Surinamese timber species - characterization and utilization. Associatie van Bos Bxploitanten (ABE), Paramaribo, Suriname. Forest Products Laboratory, Madison-

Air-dry bulk density (12 -15 % u): 0.35-0.38-0.45 g/cm³

Compressive strength u12-15 : 28-34-40 N/mm².

Flexural strength u12-15 : 48-59-70 N/mm².

Modulus of elasticity (bending) u12-15 : 8200-10100-11800 N/mm².

Hardness (JANKA) ⊥ converted: 2.0-3.0 kN.

Hardness (BRINELL) ⊥ at fiber u12-15 : 13-17 N/mm².

Drying shrinkage (radial): 1.6-2.8 %.

Drying shrinkage (tangential): 3.1-4.4 %.

Differential shrinkage (radial): ≈ 0.11 %.

Differential shrinkage (tangential): ≈ 0.25 %.

Natural durability (DIN-EN 350-2): corresponds to class 5.