Float glass or white glass?

What is Float Glass?

Glass is indispensable in decoration. The most basic is doors and windows. There are many kinds of glass, such as ordinary glass, artistic glass, tempered glass, etc. How much do you know about float

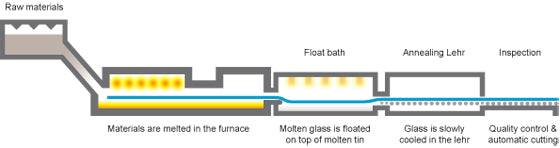

It is prepared with sea sand, quartz sandstone powder, soda ash, dolomite and other raw materials, and is melted at a high temperature in the melting furnace. The molten glass flows continuously from the kiln to and floats on the molten metal surface, spreading out into a flame-polished glass ribbon with uniform thickness , After cooling and hardening, it is separated from the molten metal, and then annealed and cut into a transparent colorless flat glass.

The forming process of float production is completed in a tin bath filled with protective gas. Float glass is widely used, including tinted glass, float glass, float glass/car windshield grade, float glass/various deep processing grades, float glass/scanner grade, float glass/coating grade, float glass French glass/mirror grade. Among them, ultra-white float glass has a wide range of uses and broad market prospects. It is mainly used in the fields of high-end construction, high-end glass processing and solar photovoltaic curtain wall, as well as high-end glass furniture, decorative glass, imitation crystal products, lamp glass, precision electronics industry, Special construction, etc.

Float Glass Fabrication

dolomite and other mineral melt them in glass furnace by a tempered of 1800℃,the bobbles rise get away from and impurity settle under the furnace,the glass float on the surface of tin material,it's spread under the works of gravity and tension form the flat glass the finally,even thickness,polished surface,no bobble.no scratch and no wave, HHG, manufacture , clear float glass, , ultra-clear float glass, colour float glass, they are application for various of field, example of door,window,furniture,auto,and can be process of tempered,laminated and mirror for Architecture or optical.

Advantages of Float Glass

1. Float glass is in the tin bath, and the glass floats on the surface of the tin liquid. Therefore, this kind of glass is first of all flatness and no water ripples. It is used for making mirrors and automobile glass without losing shape, which is a major advantage of it.

2. The ore quartz sand selected for float glass has good raw materials. The produced glass is pure and has good transparency. Bright and colorless. There are no glass boils, bubbles, etc.

3. Float glass is compact and heavy in structure and smooth in hand. The thickness of the same thickness per square meter is heavier than that of a flat plate, which is easy to cut and not easy to break.

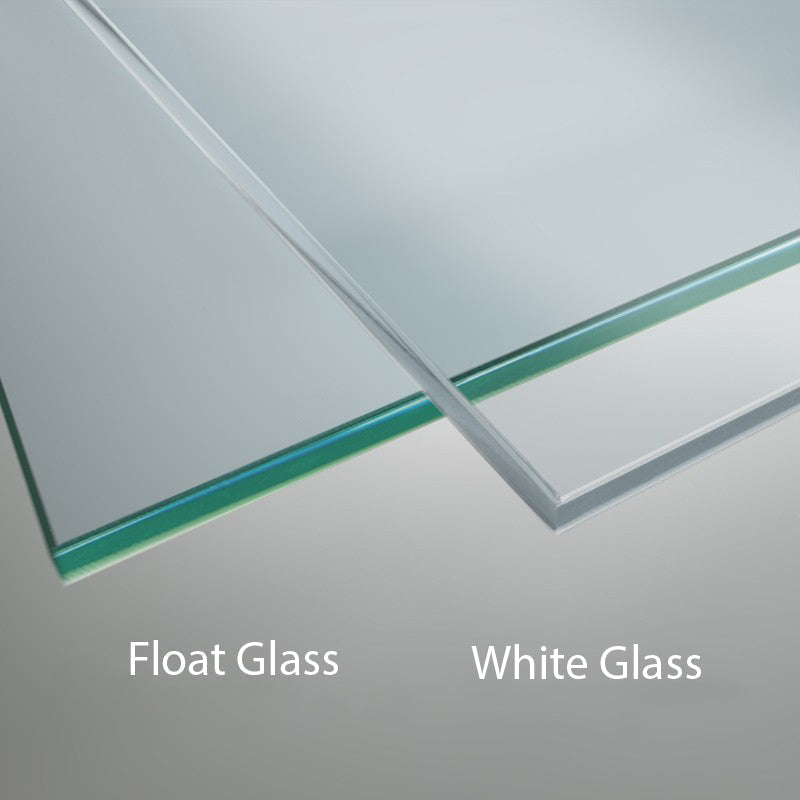

The difference between float glass and ultra-white glass:

What is ultra-white glass?

Ultra-white glass also possesses all the machinable properties of high-quality float glass, has superior physical, mechanical and optical properties, and can be subjected to various deep processing like other high-quality float glass. Such as tempering, coating, color glaze, hot bending, laminating, hollow assembly, etc.

In the field of architecture, ultra-white colored glaze is not only energy-saving and environmentally friendly, but also allows architectural design to incorporate fashionable and avant-garde architectural styles and design concepts. The combination of ultra-white glass with superior optics and optoelectronic technology in the optoelectronic curtain wall shows a new and promising field.

The difference between float glass and ultra-white glass:

In terms of appearance, the biggest difference between colorless float glass and ultra-clear float glass is transparency. The former is not strictly required. Usually the visible light transmittance is 89% (3mm), while the ultra-white has strict requirements. There are also strict regulations on the iron oxide content that causes the glass to color (blue, green): the visible light transmittance is not low At 91.5% (3mm), the iron oxide (Fe2O3) content is not higher than 0.015% (normal float is about 0.1%, which is 10 times higher).